Competitive edge for high-end film production

25 Okt 2018

Reference upgrade for Suzhou Kunlene (member of Indonesia based PT Indopoly Group)

With a group installed capacity of >100,000 tons per year, the Indonesian based PT Indopoly Group is well known for their high performance BOPP and BOPET products and excellent customer support. Aiming on further enhancing film quality, yield and production efficiency of specialty BOPP films, Suzhou Kunlene and Brückner Servtec teamed up to raise potentials of existing production lines.

The project started out with a professional on-site audit by Brückner Servtec process specialists, listening to Suzhou Kunlene challenges and evaluating the actual production situation and setup. Quick wins were achieved by directly implementing first improvement recommendations. A detailed report elaborated by Brückner Servtec and Suzhou Kunlene specialists subsequently showed options with high impact on achieving Suzhou Kunlene’s objectives and provided a solid decision-making basis.

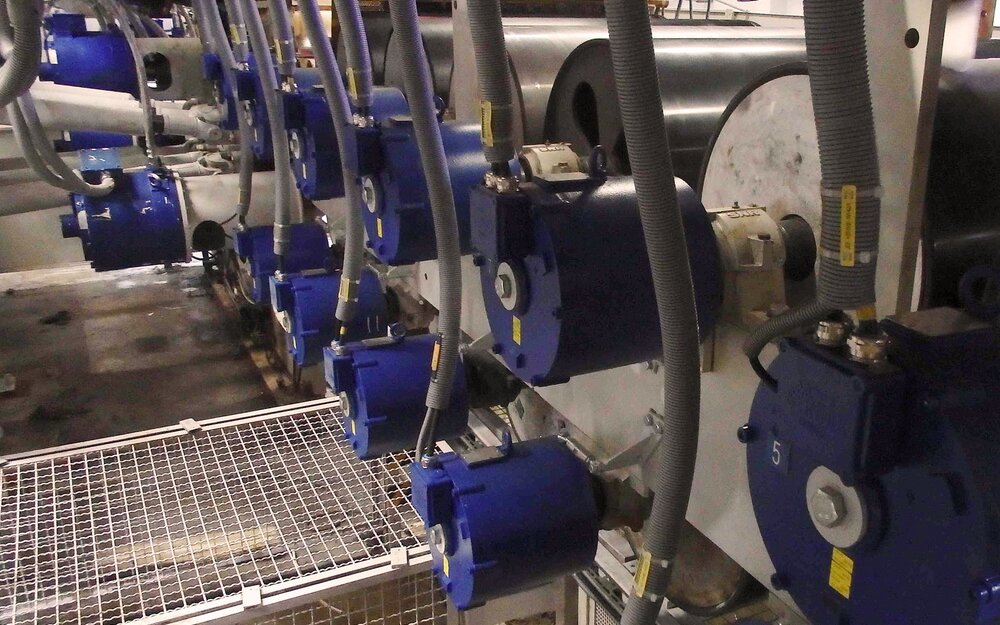

Suzhou based BOPP line, which has been in production for 15 years, received state-of-the-art direct drives and additional preheating rolls to improve the film quality. A modern LIWIND system ensures best winding quality at all production speeds and for all products. The operations efficiency increased by the use of a state-of-the-art IPC system, together with software and setup improvements for main- and co-extrusion. The overall energy consumption was also significantly reduced by the measures taken.

Considering the tight production schedule of Suzhou Kunlene, the upgrades and enhancements were achieved within the shortest time. As per high commitment and perfect cooperation of all participants, the startup was still ahead of schedule.

The line is back in production with higher efficiency and better performance than ever before.

Brückner Servtec team thanks Suzhou Kunlene for this remarkable joint success!

总部位于印尼的PT Indopoly 集团,拥有超过10万吨的年产能,以性能卓越的BOPP和BOPET产品及出色的客户服务而闻名。为进一步提高特殊BOPP薄膜的质量,合格率和生产效率,苏州昆岭薄膜和布鲁克纳服务技术有限公司通力合作提升了现有产线的潜能。

项目伊始,布鲁克纳服务技术有限公司的工艺专家即进行了专业的现场诊断,认真聆听了苏州昆岭面临的挑战,评估实际生产现状与生产线配置。第一项改进建议一经实施便取得立竿见影的效果。由布鲁克纳服务技术有限公司和苏州昆岭专家共同完成的一份详尽报告中,提出了对苏州昆岭实现目标产生严重影响的可能因素,为后续的决策提供了坚实基础。

苏州的BOPP生产线,已运行15年之久,更换了最新水平的MDO直驱电机并加装预热辊来提升薄膜质量。

最先进的LIWIND(线性收卷)系统确保在任何线速生产任何产品时都能获得最佳收卷效果。 通过使用最先进的IPC系统,加之对主挤和辅挤的软件优化与设置改进,产线运行效率得到明显提高。总体能耗也通过有效措施而大幅降低。

鉴于苏州昆岭紧张的生产计划,此次升级改造服务在最短时间内实现目标,完成任务。得益于各方的高度敬业与完美合作,开机依然提前于原计划。

目前产线已恢复生产,效率更高,性能更好,前所未有。

布鲁克纳服务技术团队感谢苏州昆岭通力合作取得这一非凡的成功。

Suzhou Kunlene: “The line upgrade is a very successful project for us and we thank Brückner Servtec so much for all their team’s hard works as well as the valuable supports towards this whole upgrade.”

Erich Huber / Senior Service Manager: “The early involvement and high dedication of Brückner Servtec and Suzhou Kunlene specialists throughout the project led to remarkable success.”

苏州昆岭: 产线升级项目非常成功,我们十分感谢布鲁克纳服务技术团队的辛勤工作和对全面升级给与的大力支持。

艾瑞希 胡博/高级服务经理: 布鲁克纳服务技术团队与苏州昆岭专家的早期参与和由始至终的高度敬业使得这个项目取得巨大的成功。