Line availability is the thing that counts

03 Sep 2020

A wide variety of upgrades and services to keep the film production up

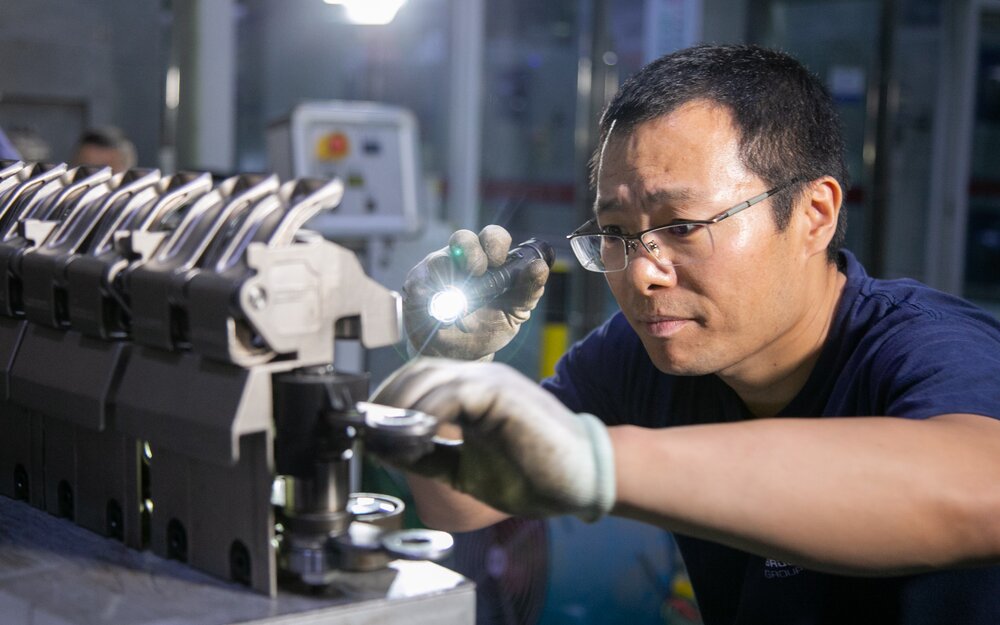

Relying on the availability and efficiency of a film production line is fundamentally necessary for a manufacturer’s success. Brückner Servtec’s upgrade and service solutions raise and keep a line's performance at the highest level, at the same time reducing the use of energy and resources as well as keeping waste at a minimum.

A whole range of state-of-the-art technologies for existing film stretching lines are available for the individual needs. A short selection:

- Virtualization

- Several line audits

- An integrated process control system (IPC)

- Clip & chain overhaul

- Extrusion upgrades

- On-site services

Thickness Gauging & Control is another major topic when it comes to reconciling availability and quality. High quality levels can only be maintained if the thickness measurement is kept in good and reliable working condition. Brückner works together with all leading suppliers on the gauging market. In this way, the best technical measurement solution, tailored to the specific needs of a film producer’s applications can be offered.

The benefits:

- Absolutely latest technology

- Secured spare parts situation

- Compliance with regulatory and approval requirements

Beyond all that: If integrated into Brückner’s IPC system, a thickness measurement upgrade ensures super-fast thickness control with automatic die bolt control, the availability of the thickness data together with all other production data in one common database – best prerequisite for stable and safe line operation.

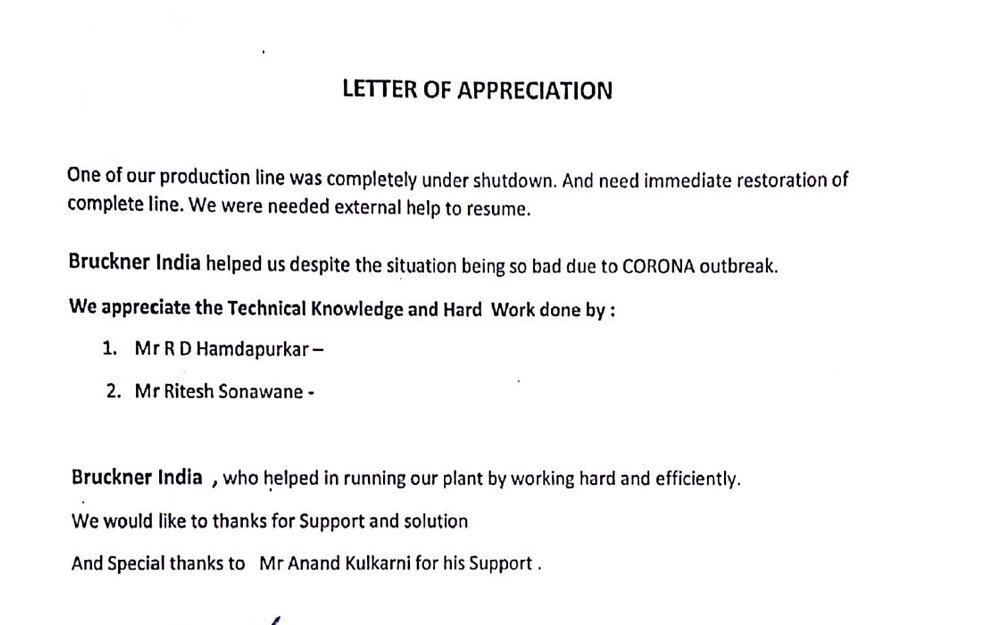

There is other good news too: Now even in times of covid19 pandemic, our local service specialists can travel following strict regulation of respective countries, customers & Brückner inhouse health measurements. Thus, they have returned to many of our customers' film stretching lines and continuing on-site service visits for troubleshooting and other services. As recently happened in India, where a plant was put back into operation after a complete shutdown within a shortest time. We are very pleased that customers have honored this with an official letter of thanks to our specialists.