请注意:本网站仅提供英文版本。

Upgrading highlights for JSC Mogilev: Gravimetric Dosing and TDO Heat Recovery System

25 Aug 2008

Film producer JSC Mogilev Viscose Fibre Plant, Belarus, recently carried out several line modifications at its 6,6m BOPP-line for improved film quality and efficiency

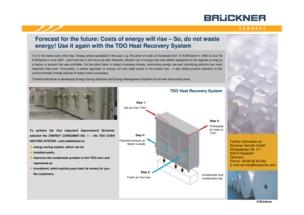

The line has been equipped with the latest gravimetric dosing system from Schenck Process, a leading supplier of dosing systems. This new technique increases film quality and dosing efficiency, since each single raw material is weighed exactly and its consumption can be optimally controlled. Another reason for JSC Mogilev, to invest in a new dosing unit, is the secured future spare parts availability, which could not be provided with the former system anymore. Worldwide rising energy prices caused JSC Mogilev to focus more on an energy saving policy and reduce the line’s energy consumption. For this purpose, Brückner’s Heat Recovery System for the TDO has been installed. The advantage of this new technology is to re-use thermal energy. Due to high energy savings, the investment pays back within no time. In addition to the above mentioned cost-saving aspect, the TDO Heat Recovery System offers several further advantages:- Improved film quality due to reduced temperature differences in TDO

- Less maintenance in TDO because of controlled condensate absorption and removal

- Environmentally friendly system, since there are less emissions to the environment